Forged cold mill roll

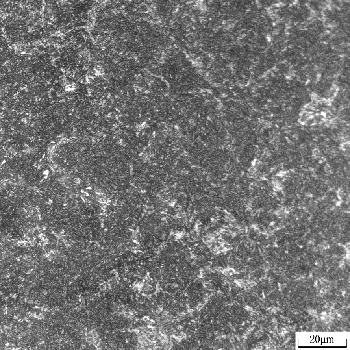

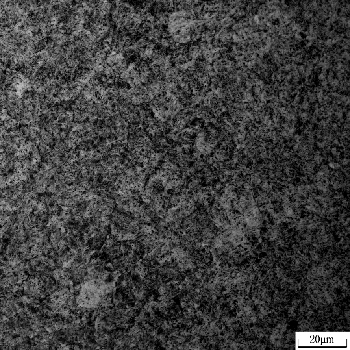

The forged cold roll including work roll, intermediate roll and backup roll. In order to ensure product quality, the mill rolls provided by Yelong are all from the beginning of the ingredients, through smelting, LF/VD, ingot casting, electroslag remelting, forging, post-forging heat treatment, rough machining, preparatory heat treatment, semi-finishing, induction quenching, sub-zero treatment, tempering, finish machining, packaging and other processes. The working layer can reach above 30mm. The grain size is controlled at grade 9.5-11 and martensite grade≤2 to ensure the wear resistance and anti-accident performance of the roll.

Chemical composition

|

material |

C |

Si |

Mn |

Cr |

Ni |

Mo |

V |

|

Cr2 |

0.8-0.95 |

0.15-0.6 |

0.2-0.5 |

1.7-2.4 |

≤0.25 |

0.15-0.5 |

0.05-0.15 |

|

Cr3 |

0.5-0.95 |

0.2-0.9 |

0.2-0.9 |

1.8-3.5 |

≤0.6 |

0.15-0.6 |

0.05-0.15 |

|

Cr5 |

0.5-0.95 |

0.2-0.9 |

0.2-0.9 |

4.8-5.4 |

0.15-0.6 |

0.15-0.6 |

0.1-0.3 |

Yelong International

E-mail:

Xingtai Office:

B1207-1208 Fengji Bldg, Zhonghua Road, Xingtai,Hebei, China 054000

Beijing Office:

B402-1078 Government Office Bldg, Shicheng Town, Miyun District, Beijing, China

Qingdao Office:

B3318 Wanda Plaza, No.33 Lianyungang Road, Qingdao, Shandong, China 266034

© 2019 Qingdao Yelong International Co., Ltd. 鲁ICP备20013487号-1 Powered by:www.300.cn