Details

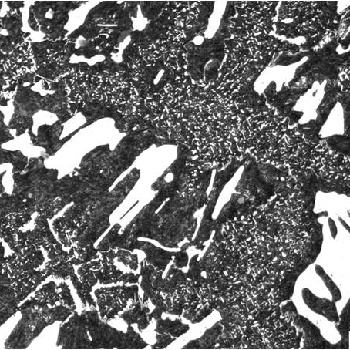

The working layer of HSS content 1.5-2.5% carbon and a large number of Cr, Mo, V, W and other strong carbide alloy elements, a lot of MC and M6C alloy carbide with high micro hardness distribution on the martensite and banite matrix and increased wear resistance. The graphite particles of HSS are finer and more dispersed. During rolling process, graphite particles play a good function of lubrication, and effectively improved surface quality. The wear resistance was improved by 3-5 times than ICDP rolls.

Chemical composition

|

material |

C |

Si |

Mn |

Cr |

Ni |

Mo |

V |

W |

|

HSS |

1.5-2.5 |

0.3-0.8 |

0.5-1.0 |

4.5-6.5 |

0.5-0.8 |

2.0-4.0 |

3.0-4.5 |

3.0-5.0 |

|

S-HSS |

0.6-1.2 |

0.3-0.8 |

0.4-1.0 |

4.0-6.5 |

0.5-0.8 |

1.5-2.0 |

2.5-3.0 |

1.0-1.5 |

Related

MESSAGES

We will contact you within one working day. Please pay attention to your email.

Yelong International

E-mail:

yelong @ yelongintl.com

Xingtai Office:

B1207-1208 Fengji Bldg, Zhonghua Road, Xingtai,Hebei, China 054000

Beijing Office:

B402-1078 Government Office Bldg, Shicheng Town, Miyun District, Beijing, China

Qingdao Office:

B3318 Wanda Plaza, No.33 Lianyungang Road, Qingdao, Shandong, China 266034