ROLL INSPECTION

TIME:

2020-07-10

Advances in nondestructive testing have improved the methods used by both the roll manufacturer and the roll shop to evaluate the quality of the roll material. The objective of a proper roll maintenance program is to detect the earliest stage of a roll problem and to prevent that roll from being retumed to mill service unless corrective action is made.

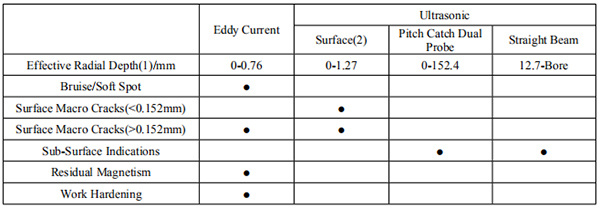

Advances in nondestructive testing have improved the methods used by both the roll manufacturer and the roll shop to evaluate the quality of the roll material. The objective of a proper roll maintenance program is to detect the earliest stage of a roll problem and to prevent that roll from being retumed to mill service unless corrective action is made. The general inspection methods that can be employed by a roll shop are eddy current, sur face wave ultrasonic, dye penetrant, etch, magnaflux and hardness testing. With all of the inspection techniques available, the quickest, most accurate and reliable are the eddy current and ultrasonic inspection. When used together, all surface conditions that could be detrimental to the roll or the rolled product during mill service can be detected with 100% accuracy. Dye penetrant, and etch testing have the benefit of being an inexpensive method for inspection, however, they are time consuming and not always 100% reliable, therefore, they should be used in conjunction with eddy curent and ultrasonic inspection.

Remark: (1)F unction of equipment parameters (F requency crystal, type crystal, probe design)

(2)Circumferential Direction (3 scans required)

Longitudinal Direction (2 scans required)

1.Eddy current inspection

Eddy current testing is an inspection method for locating indications such as soft areas (bruises), wide cracks and magnetism and is perfiormed after completion of the grinding operation. While the roll is still in the grinder, a dual wire differential probe is brought close to the roll surface on one end of the roll body. With the roll rotating at a set speed, the probe is then slowly traversed across the entire length of the roll body. Synchronization of the traverse rate and roll RPM is designed to insure that every point on the roll surface is passed between the dual wires. As the probe traverses the roll body, eddy currents are induced on the roll surface between the wires by the application of an altermating current. Instantaneous changes in either the electrical conductivity or the path length between the wires can be detected and are displayed on two separate channels named the Pinch/Bruise channel and the Crack/Spall channel respectively. The specific procedures for performing eddy current inspection are dependent on the eddy current equipment used and is provided by the manufacturer.

2.Surface wave ultrasonic inspection

Surface wave ultrasonic inspection is perfomed using a transducer attached to a 90 surface wedge and is the most accurate method for detection of surface cracks. Surface wave ultrasonic inspection transmits high frequency sound waves around the circumference to detect conditions that reflect or absorb the sound waves. All interfaces will reflect or scatter the waves to some degree. This includes cracks, inclus ions, grain boundaries and other discontinuities. Metal-to- air interfaces (cracks) reflect most of the sound wave while metal-to-solid interfaces (inclusions) partially reflect the sound waves. The reflected sound wave is then retumed to the transducer and is displayed on the testing screen as a spike.

3.Dye penetrant inspection

Dye penetrant inspection can be performed at any time (after the grinding operation is most common) and is used to highlight cracks on the roll surface. A red colored dye penetrant is applied to the roll surface and the dye enters crack interfaces through capillary action. After a specifice amount of time, the roll is wiped dry with clean, dry cloths. The dye will seep back out of the cracks through reverse capillary action. Developer is applied to the surface and the cracks are highlighted as red lines on the white background. Dye penetrant testing can also be done using a florescent dye. The cracks are then highlighted using a florescent black light instead of developer. Dye penetrant inspection is accurate at highlighting large, wide cracks, however, if the crack is too narrow, the penetrant cannot seep into the crack and will not be highlighted when developed. It is generally preferred to perform the test after locating sur face indications with eddy current and ultrasonic inspection. Only the general area of the indications can then be tested rather than the entire roll body.

4.Etch testing

Etch testing can be performed at any time (after the grinding operation is most common) and is used to highlight conditions on the roll surface where cracks or a change in hardness exists. When acid is applied to the roll surface, softer areas will“bum”or“darken”at a faster rate than harder areas leaving a differential etch appearance. Cracks are also highlighted during an etch test when reagent enters the crack interface through capillary action. Once the acid is cleaned from the surface, the residual acid within the crack seeps out and bums the area surrounding it. Etch testing is accurate at highlighting bruises and large, wide cracks, however, if the crack is too narrow, the acid cannot enter into the crack and it will not be highlighted. It is generally preferred to perform the test after locating surface indications with eddy current and ultrasonic inspection. Only the general area of the indications will then need to be tested rather than the entire roll body.

5.Hardness test

Hardness testing should be performed before and after the grinding operation. It is used t determine the overall hardness of the roll as well as verifying the existence of localized hardness differentials (bruises, work hardening, etc.). The typical methods of hardness testing include indentation (Rockwell - HRc and Vickers - HV) and rebound testing (Equotip- HLd and HLe, Shore - HFRSc and HSd). Rockwell testing is not generally used in the roll shop due to the special surface requirement needed for accurate testing and the time involved to prepare a test spot. The Equotip and Shore tests are the most commonly used hardness testing methods. The rebound tests indicate the hardness by dropping a small impact device or“hammer”onto the roll sur face and measure the height (Shore) or speed (Equotip) of the rebound. The test can be performed on any clean surface and should be performed multiple times to obtain the average hardness of the area being tested.

TAG:

Previous:

Previous:

MESSAGES

We will contact you within one working day. Please pay attention to your email.

Yelong International

E-mail:

yelong @ yelongintl.com

Xingtai Office:

B1207-1208 Fengji Bldg, Zhonghua Road, Xingtai,Hebei, China 054000

Beijing Office:

B402-1078 Government Office Bldg, Shicheng Town, Miyun District, Beijing, China

Qingdao Office:

B3318 Wanda Plaza, No.33 Lianyungang Road, Qingdao, Shandong, China 266034